SMT Smart Automatic Solder Paste Adding Unit For Solder Paste Printer Stencil Printer

△ Run add - Increase capacity

Change the bottle for 30 seconds, the whole line does not stop, and the production capacity is not wasted

△ Program control - stable and reliable

Add it with the print. Call the police

△ Uniform addition - stable tin content

The tin output is stable and controllable, and the tin adding frequency can be set

△ Closed operation - temperature and humidity controllable

Temperature and humidity real-time monitoring, printing machine internal overtemperature alarm

Specification

1.Drive mode: pure electric, automatic control, one-click tinning

2.Trigger mode: ① upper and lower sensor trigger,

② Solder paste rolling diameter detection trigger (optional)

3.Control mode: customized touch screen +PLC integrated machine, equipped with rich interfaces

4.Drive unit: Custom stepper motor with feedback, custom reducer, imported screw slide

5.Operation mode: automatic operation, fixed point/multi-point tinning, first tinning, power off memory6.Minimum tin output: 2g

7.Tin accuracy: 2g±0.2g (measured error is less than 7%)

8.Bottle bottom residue: about 3g (measured about 2g, solder paste viscosity slightly affected)

9.Half bottle mode: pressure weighing sensor, realizing the automatic addition of half bottle solder paste

10.Risk assessment: no tin drop (set reasonable parameters according to the viscosity characteristics of the solder paste)

11.Networking applications: Support for online monitoring or MES data link (optional)

12.Monitoring application: Equipped with temperature and humidity monitoring module, supporting data storage

13.Application type: process improvement application

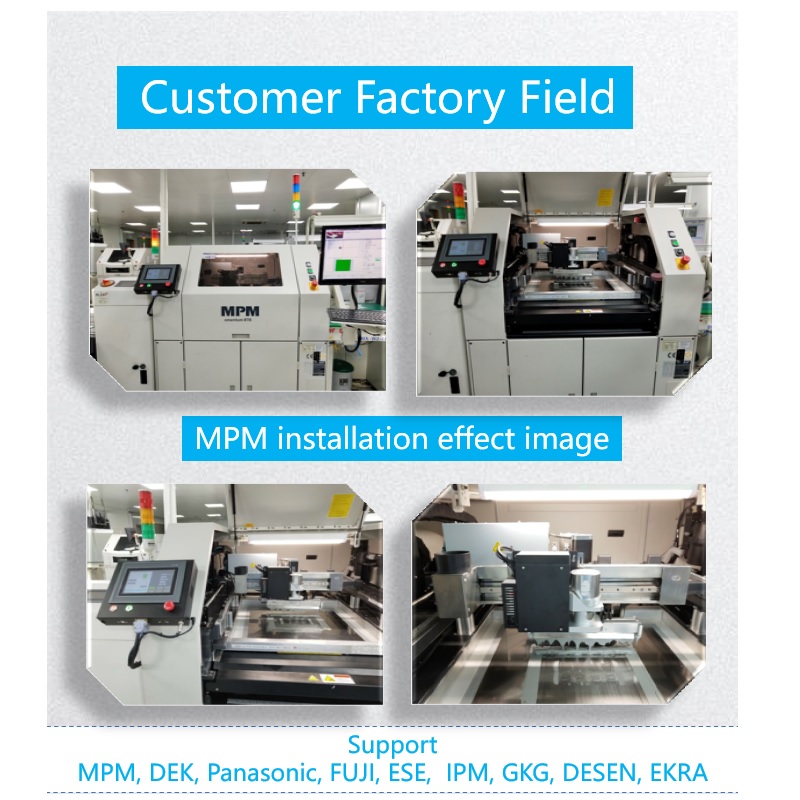

14.Application: All brand printing presses can be installed, built-in mainstream brand solder paste bottle parameters

15.Air source: pure electric, no gas

16.Power supply: 220V, 50/60Hz, 100W