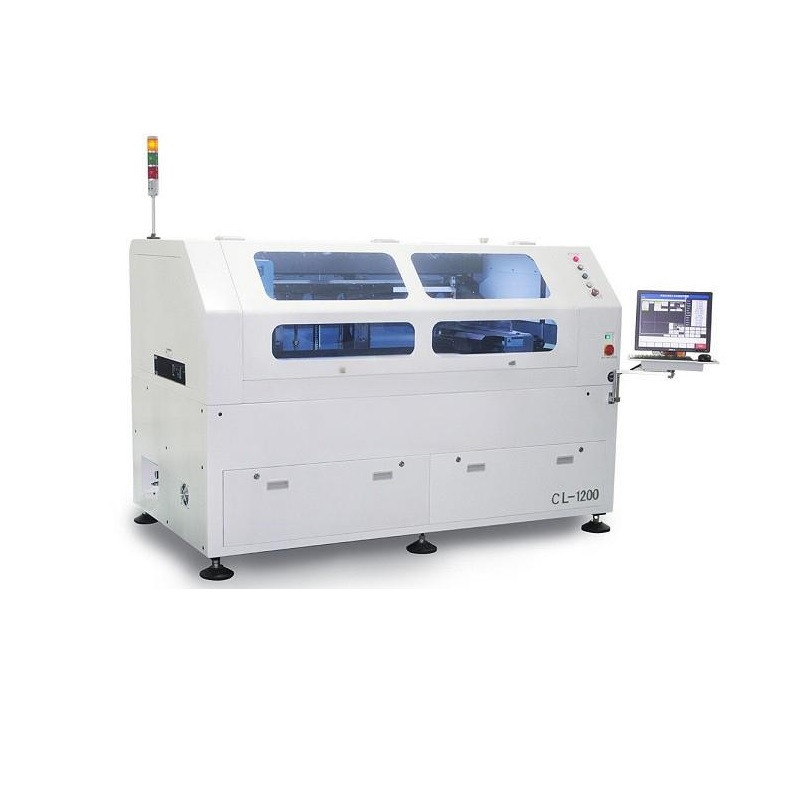

HC Solder Paste Printer CL-1200 For Length 1.2m PCBA Manufacture

HC Solder Paste Printer CL-1200 For Length 1.2m PCBA Manufacture

Used Machine

Specification

Basic features of the CL-1200 printing press:

The PCB size compatibility range is wide, supporting PCBS of different thicknesses from 80mm X 50mm to 1200mm X 340mm.

2. High-precision printing resolution. High positioning accuracy, repeat positioning accuracy ±0.01mm; Printing accuracy: 0.03mm. Supports glue printing.

3. Fully automatic control can enhance production efficiency, control quality and save costs: automatic steel mesh positioning; Automatic PCB correction Automatic scraper pressure adjustment; "Automatic printing; Automatic steel mesh cleaning (dry cleaning, wet cleaning);

4. It adopts the suspended printing head independently developed by Huancheng Company and the programmable cylinder pressure automatic adjustment system, which can provide real-time feedback on pressure and automatically balance the squeegee pressure online. The pressure control is precise and can achieve a perfect solder paste forming effect.

5. The programmable motor controls the separation speed and stroke of the scraper from the steel mesh, which can flexibly realize various demolding methods.

6. The multi-functional PCB fixed positioning system makes PCB positioning convenient, fast and accurate.

7. Upper and lower visual positioning system.

8. Built-in image processing system.

9. Supports 2D and SPC functions.

The solder paste printing range of the CL-1200 printing press

SMT process production and processing of surface mount components such as resistors, capacitors, inductors, diodes, transistors, etc. : 0201, 0402, 0603, 0805, 1206, and other specifications and sizes;

2. IC: Supports SOP, TSOP, TSSOP, QFN and other packages, with a minimum Pitch of 0.3mm. Supports BGA and CSP packaging, with a minimum Ball diameter of 0.2mm.

3. Printing size: 80mm x 50mm to 1200mm x 340mm;

4. PCB specifications: Thickness 0.6mm to 6mm

5. FPC specification: Thickness less than 0.6mm (with fixture)

Application scope of CL-1200 printing machine

Production and manufacturing of LED, mobile phones, communication devices, LCD TVS, set-top boxes, home theaters, automotive electronics, medical power equipment, aerospace and other products/equipment, as well as production and processing of general electronic products.

CL-1200 printing machine parameters:

Repeat positioning accuracy: ±0.01mm (CPK=2.0, 6σ)

Printing accuracy: ±0.025mm

Production cycle time/excluding cleaning: <12 seconds

Cable changing time: less than 5 minutes

Steel mesh dimensions: 1100x300mm-1500x750mm(standard), 730X300-1500X750mm(optional)

PCB printing size: 80x50-1200x340mm

PCB curvature: <1% (with the diagonal length as the reference)

Edge clearance of the board: 3mm

Track transmission speed: 50-1200mm/sec programmable control

PCB positioning methods: Elastic side clamping/vacuum suction/Z-direction sheet pressing/magnetic pin/side support block/flexible automatic pin (optional)

Printing head: Programmable electric control printing head (standard)/Programmable electrical combination control printing head (optional)

Scraper speed: 10-200mm/sec

Scraper pressure 0-15KG program control (standard configuration) (closed-loop pressure feedback optional)

Steel mesh separation speed: 0.1-20mm/sec (programmable control)

Cleaning methods: Dry cleaning, wet cleaning (programmable for any combination)

Workbench adjustment range: X=±8mm,Y=±10mm, Θ=±2°

Camera system: CCD camera/telecentric coaxial vision system/Four independent coaxial/annular LED light sources

Air usage: 4-6kg/cm ²

Gas consumption: approximately 0.07m ³ /min

Power supply: AC: 220, ±10%,50/60HZ 1Φ1.5KW

Machine dimensions: 2220mm(W)x1220D x1500(H)

Machine weight: Approx:1500kgs

CL-1200 printing machine configuration:

Programmable scraper pressure automatic adjustment suspended scraper printing head.

(1) Programmable electronically controlled automatic pressure adjustment system. The pressure control is accurate.

(2) The pressure of the left and right scrapers is independently adjusted to ensure that the pressure imbalance caused by the fatigue deformation of the scraper material is avoided, thereby preventing the difference in printing between the front and back.

2. Standard stainless steel scraper, with a unique design, extends the service life of the blade.

3. Visual alignment system.

4. Platform X/Y/θ automatic correction system.

5. PCB clamping and support device.

-Magnetic pin;

-The flexible clamping device on the side of the PCB ensures that the PCB will not bend or deform during clamping.

-Powerful vacuum suction nozzle;

-Elastic movable Z-direction tablet press;

-Flexible automatic ejector pin (optional);

6. The numerical control guide rails adjust the transportation width and speed.

7. Three programmable and freely combinable steel mesh cleaning systems: dry, wet and vacuuming.

8. Industrial control computer,Windows XP Chinese-English interface operating system.

9. Built-in software diagnostic system.

10. Supports 2D and SPC software functions.

11. Standard SMEMA connection interface.