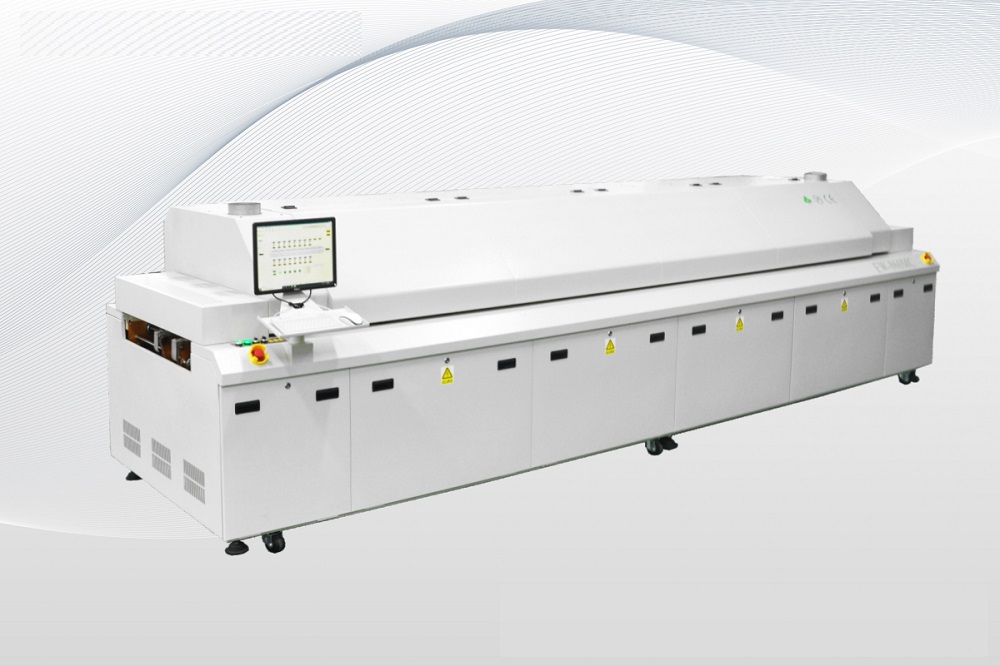

8 Heating Zones Reflow Low Energy Consumption Reflow

Patented hot-wire heating technology, independent small circulation air structure, up and down heating mode, high thermal efficiency, fast heating, About 20 minutes from room temperature to set operating temperature.

1. Taiwan Mitsukoshi special high temperature motor, direct drive hot air heating, hot air balance, low noise, small vibration, 0201 components can be used Does not shift during transportation.

2. Unique air duct design, imported volute air with three layers of air equalizing device, uniform air, large heat capacity, preheating zone, constant temperature zone and welding

3. Standard with two forced cooling zones, the cold air temperature of the cold air outlet can reach 5℃, and the cooling rate of the first cooling zone can reach -5℃/S.Effective filling a variety of lead-free processes.

4. Suitable for the temperature curve of various models, double welding zone or three welding zone Settings, minimum eight-line PROFILE TEST Delta T Up to 8 ° C, the connection curve test is especially corresponding to the Japanese or European and American standard lead-free welding process.

5. Adopt the latest design of special transport guide rail, made of high temperature and wear resistant aluminum alloy, high rigidity without deformation.Width adjustment of guide The system adopts pinion and rack coaxial width adjustment device to ensure that the parallel of the guide rail is up to ±5MM, which effectively prevents the occurrence of clamping plate and falling plate. And it is equipped with automatic and manual width adjustment devices.

6. The transportation system adopts stepless frequency conversion speed regulation, Japan Dongchuan motor drive, high-quality stainless steel chain and SUS316 material Stainless steel mesh belt synchronous transport, to further ensure smooth transport. And equipped with UPS uninterruptible power supply and hand shake out function, can be effective prevent PCB from baking in the furnace due to sudden power failure.

7. With timing automatic drip oil and PCB counting function.

8. Using industrial computer control, Dell LCD display, WindowsXP operating system, with flexible curve testing and powerful dynamic curve analysis, all data can also be printed and saved to meet the lead free process.

9. All electrical components are imported, and all signal lines are shielded to ensure long-term SMT 24 hours stable by operation, high temperature parts for three years free warranty.

Remark: Term is FoB shenzhen, with wooden case & vacuum packing, 100% new reflow, Made in China

Specification

[ Heating part parameter ]

Heating zone: Up 8 / Down 8

Heating length: 2710mm

Cooling zone: 2

[ Conveyor parameter ]

Max.width of PCB: 450mm

Rail adjust range: 50-450mm

Conveyor direction L→R ( R→L.option )

Conveyor rail fixed: Front or rear

Height of conveyor: Mesh 880±20mm Chain 920±20mm

Transport system: Chain+Mesh

Conveyor speed: 0-2000mm/min

[ Controlling parameter ]

Power supply: 3 Phase 380V 50/60Hz

Power of start up: 44KW

Power of consumption of operation: Approx. 6KW

Control fashion: Industry PC

Warm-up time: Approx. 20 Mins

Range of temperature control: Room Temperature-350℃

Temperature control: Siemens industrial temperature control module control, SSR drive

Precision of temperature control: ± 1℃

Temperature distributing error:± 3℃

Trouble alarm: Abnormal temperature (ultra-high temperature or ultra-low temperature after constant temperature)

Board drop alarm: Option

[ Machine size weight ]

Weight Approx. 1800kg

Dimension(mm) : L5200×W1350×H1520

[ Technical Item ]

PCB Width: Single Conveyor 50~450mm, Mesh 0~450mm

PCB PCB board component height limit: up 20mm,down15mm