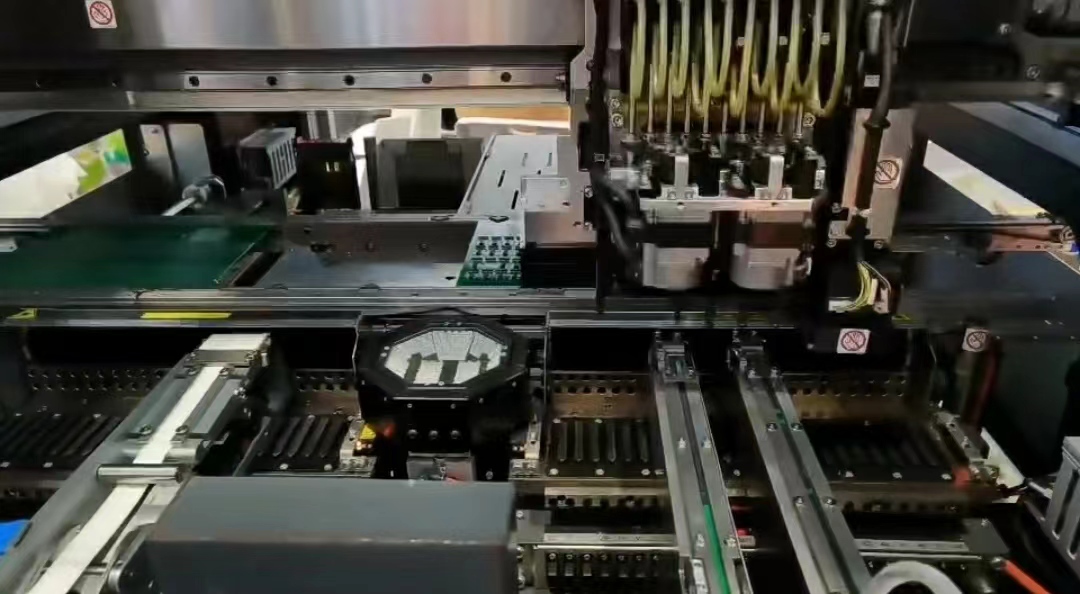

New Design Continuously Work Without Stopping Stick Feeder For YAMAHA YS YSM Series Machine

The utility model relates to an automatic multi-tube feeder for feeding a chip to pick and placement machine, which can especially solve the problems of using a traditional stick feeder, such as large space occupation, less tube component in one load, low efficiency of the feeding section, high component throwing and high defective products. The feeder can be widely used in the field of feeding a tube-component to pick and placement machine.

1. The tube loading feeder has the tube pulling structure of discharging the tube from the side, which takes up less space and has high reliability. It can be applied in the stick feeder to realize the automatic discharge and loading of the tube components.

2. The whole body of the stick feeder adopts an integrated aluminum alloy structure, light and thin design scheme, and the body width is only 70MM, which solves the problem that the size of the feeder occupy a large space and can't be miniaturized, and can optimize the placement machine feeder station space.

3. Double tube channel design, the rear section of the feeder is loaded with IC tube component layer, the rear section adopts the blowing mode to send the component to the front conveyor belt, the front section of the sensor senses the component, step motor stop conveying, and the cycle work realizes the automatic feeding.

Application: YS12 YS12F YS12P YS100 YS88 YS24 YS24X YSM10 YSM20 YSM20R

Specification

Feeder parameters:

【Working mode 】

The rear section adopts the blowing mode to send the component to the front conveyor belt, the front section of the sensor senses the component, step motor stop conveying.

【Transfer motor】 Stepper motor

【Power supply 】 DC240V MIN:1A-MAX:15A

【Air pressure 】 5~6Kpa

【Driving mode】 Air and Electricity

【Working environment】 20℃~32℃

【Transfer speed】 High speed :75MM/S Medium speed :50MM/S Low speed :25MM/S

【Continuous feeder speed】0.2 seconds /PCS(SOP8)

【Control unit】 Self-developed control system

【Applicable Components】 Tube components

【IC tube width】 Max. 12MM

【IC tube Thickness】 Max. 7MM

【IC tube length】 490MM-545MM

【Three specifications of IC body width】

1:SOP8-16 component thickness 1.45-155MM Component width 6MM

2:SSOP16-24 component thickness 145-155MM Component width 6MM

3:TSSOP20-24 component thickness 095-105MM Component width 6.4MM

【IC tube capacity】47 IC tubes can be placed on the 3.5mm thick tube (clamp height: 165mm)

【Dimension】L996mm W70mm H309mm

【Weight】About 10KG